What Is a Sorter System and How It Optimizes logistics?

In modern logistics, sorting systems have become essential for optimizing logistics processes for shipping products to customers. These automated sorting systems speed up product flow, reduce picking and shipping errors, and significantly improve operational efficiency. Whether you manage a high-volume logistics centre or are looking to improve your warehouse performance, understanding what a sorter is and how the different sorters available on the market work can make all the difference to your company's supply chain.

At JHernando, we can help you find the sorter that best suits your specific needs and facilitate its integration into the layout of your facilities.

A sorter is a set of automated mechanisms and technologies designed to identify, direct and distribute individual units (such as packages or items) to specific destinations within a logistics process. The main objective of a sorter is to optimise the flow of materials by ensuring that each item is directed accurately and efficiently according to predefined criteria such as final destination, physical characteristics, or operational priorities. It works using synchronised sensors, information readers (such as barcodes or electronic tags) and actuators that allow real-time decision-making without interrupting the flow. Sorters are an absolutely essential tool for warehouse optimisation.

The most commonly used sorters include pop-up sorters, which lift or divert packages individually; tilt tray sorters, which are ideal for handling small or irregular items; slide tray sorters, which are similar but have trays that allow products to be conveyed much more smoothly to their destination; shoe sorters, which are highly accurate and fast for processing large volumes; narrow belt sorters, which have a shorter passage between lanes than other conventional sorters; and crossbelt sorters, which are versatile and can handle a wide variety of sizes and shapes. There are also other types of sorter that combine these technologies or have been designed to meet specific objectives, such as those for the ecommerce sector or those that are specifically designed to take up less space in facilities.

Below is a brief definition of each type and its most common use.

POP-UP SORTER

The pop-up sorter redirects items using a set of rollers arranged in a row at each diversion point. These rollers, integrated into the conveyor system that moves the load, automatically rise to align and guide each package to its assigned destination. As the direction of the rollers can be easily reversed, it allows for quick switching between product entry and exit sorting processes, making it a highly sought-after solution for reverse logistics.

Compact, fast and accurate, it is ideal for logistics operators with high shipment volumes or for the ecommerce sector. It is also commonly installed in courier-distribution companies, Food&Beverages, or in laboratories or pharma logistics companies, as thanks to its modular system, this sorter easily adapts to complex environments with automated or semi-automated manufacturing.

JHernando offers pop-up sorters with pneumatic or electric diversion systems (wheels) that allow for the diversion of light or fragile products as well as larger packages. This type of sorter is becoming increasingly compact and tends to take up less space, making it ideal for smaller facilities such as last-mile facilities or those located in large cities.

Main advantages:

Main advantages:

- Fast and accurate sorting

- Space optimisation with a compact and scalable design

- Reduced errors and less manual intervention

- Improved productivity and efficiency during peak demand periods

- Easy integration with existing WMS and conveyor systems

TILT TRAY SORTER

A tilt tray sorter is an automated goods sorting system comprising moving trays that tilt to quickly and accurately deposit products in their corresponding destination locations.

Tilt tray sorters are ideal for handling small to medium-sized items, such as clothing, books, cosmetics and fragile electronic products. This makes them a key solution for sectors such as e-commerce, retail distribution and the pharma industry.

Main advantages:

- High efficiency in sorting thousands of units per hour.

- Accuracy in delivering products to specific destinations.

- Reduction of human error and operating times.

- Optimisation of space within the warehouse thanks to its compact and modular design.

SLIDE TRAY SORTER

The slide tray sorter is a sorting solution that uses sliding trays that open smoothly to drop the product into its assigned destination. This system is particularly effective for handling items of different sizes, shapes, and weights with great precision and minimal risk of damage.

The primary distinction between the tilt tray sorter and the slide tray sorter lies in their respective capabilities. While the tilt tray may encounter limitations when handling delicate or irregularly shaped items, the slide tray sorter boasts enhanced versatility, reduced product impact, and have a modular design that facilitates integration and adaptation to diverse logistics environments. It is widely used to handle fragile products and in sectors such as ecommerce, fashion, retail, food and beverages, pharmaceutical distribution and express parcel delivery.

Main advantages:

- Versatile, as it works with products of different weights, shapes and sizes.

- Careful delivery, minimising damage thanks to gentle handling.

- Precision in delivery.

- Scalable and easily adaptable to the growth of the company where they are located, allowing for expansion without major renovations.

SHOE SORTER

The shoe sorter is a high-speed automatic sorting system that works by means of sliding shoes that gently push the packages towards different exits along a conveyor belt, with great precision and without stopping the flow.

This type of sorter is especially recommended for logistics centres with high order volumes. Its key feature is its great versatility, as it can handle a wide variety of products, from small items to packages weighing up to 40 kg. Its intelligent design allows it to easily adapt to the needs of the warehouse. While its initial investment may be higher than that of other sorting systems and it tends to take up more space, it offers a clear competitive advantage in terms of greater sorting accuracy and a processing capacity of between 8,000 and 12,000 packages per hour.

It is therefore ideal for operations that require speed, reliability and efficiency.

Main advantages:

- High speed and accuracy, as it handles thousands of items per hour without errors.

- Reduces human error by automating key logistics processes.

- Has greater operational efficiency than other sorters, with less downtime and higher productivity.

NARROW BELT SORTER

A narrow belt sorter uses bi-directional rotating carriers as the carrying and sorting units, which are arranged on a specific drive main line and continuously and cyclically run to sort parcels. The sorter uses a vertical circulating layout, with a compact structure. The pitch between carriers is shorter than that of the conventional ones.

The sorter does not strictly limit parcel dimensions and can sort large parcels, small parcels, packages, and cartons at the same time.

Main advantages:

- Space-saving design, making it perfect for environments where every centimetre counts

- Accurate and reliable, resulting in fewer errors and returns

- Scalable, making it easy to adapt to peaks in demand

CROSS-BELT SORTER

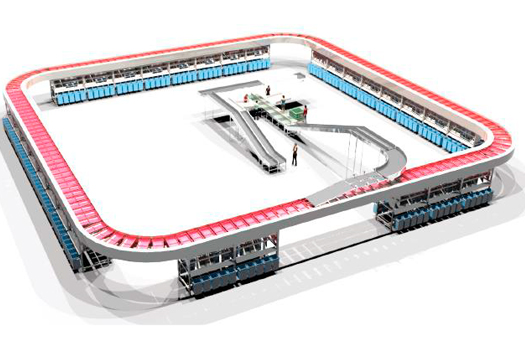

The cross-belt sorter is a sorting system that uses multiple mobile conveyor belts to move items along continuous conveyors that travel at high speed along a fixed track. It is designed to continuously process large volumes of packages, allowing for the accurate sorting of a wide variety of formats, from small envelopes to heavy boxes weighing up to 50 kg.

Main advantages:

- High operating speed of up to 2.5 m/s.

- Minimum sorting error rate of ≤ 0.01.

- Servo motorised system.

- Flexible implementation thanks to its modular design.

- Bidirectional unloading and feeding for more efficient sorting.

OTHER SORTING SOLUTIONS TO CONSIDER

At JHernando, we have spent 60 years developing the most advanced sorting systems in each area. This enables us to provide automated sorting solutions for all types of packages and the specific needs of our customers. Some of these technologies combine several of the above, while others are developed specifically to meet certain objectives, such as layout, handling of very specific packages and weights, and serving of specific sectors.

The Mushiny 3D Sorter, for instance, is a pioneering solution that JHernando distributes in Spain and Portugal. It is designed for companies that handle a large number of SKUs. Integrating it into their supply chain will improve their picking efficiency by three to five times, combining the best sorting solutions with an advanced picking system to respond to order preparation and reverse logistics needs. There is also a smaller version: the 3D Sorter Mini. This is compatible with both manual picking processes and Goods-to-Person (GTP) picking systems. Its main advantage is that it increases picking efficiency by more than 200% and sorting efficiency by more than 300%.

Other innovative sorters, such as Equinox's LR-Sorter, are based on Slide Tray Sorter technology but have been developed specifically with specific objectives in mind. In this case, adding other advantages such as greater compactness or a vertical design that maximises the number of outputs in small spaces, it becomes particularly suitable for ecommerce products (small packages, flyers, envelopes, bagged garments, fragile technological products, etc.), adapting to the market.

In conclusion, each sorter works as an intelligent distribution system that replaces or complements human intervention in repetitive high-speed tasks, and its integration into facilities improves traceability, reduces errors and increases operational capacity in virtually any sector. Hence the importance, in order to stand out from the competition and optimise the warehouse, of having the right machine for the available space and the type of product to be sorted, to facilitate the task, such as those that JHernando can offer you in terms of sorters.